WHERE IT IS INSTALLED AND WHAT MATERIALS ARE USED

Terrazzo is a building material that is mixed and poured in place for floor and walls. It consists of marble, quartz, granite, glass, or other suitable chips, mixed and poured with a binder.

Terrazzo is cured and then ground and polished to a smooth surface or otherwise finished to produce a uniformly textured surface.Terrazzo is a mosaic floor consisting of aggregate chips, such as marble, bound together with a matrix binder, such as cement. Which is then honed and polished together and sealed, creating a beautiful and lasting floor.

Terrazzo flooring has a long and rich history dating back to the renaissance and possibly further. During the renaissance Marble craftsmen brought home the scrap pieces of marble and laid them out on their terraces, sealing them with goat’s milk. Terrazzo has come a long way, but one thing remains constant, it is still one of the most beautiful and timeless floor options available.

Modern terrazzo is typically thin section and can be cementitious which is cement with modifiers, but it is most often epoxy resin. Epoxy provides a stronger matrix and also is available in more vibrant colors than cement.

FIND A CONTACTOR

MAINTENANCE & CLEANING

The long life cycle and ability to rehabilitate Terrazzo at the end of its life cycle make Terrazzo the most sustainable floor option available. Recycled aggregate can also be utilized for Earth friendly construction.

Cleaning and maintaining of terrazzo is simple and inexpensive. It is typically cleaned no different than any other hard surface. There are many ways to maintain terrazzo for long term maintenance. High performance sealers can be used that can be scrubbed and buffed over long periods of time. Also floors waxes can be used to revitalize new or existing terrazzo.

Terrazzo craftsmen create walls, floors, patios, and panels by exposing marble chips and other fine aggregates on the surface of finished concrete or epoxy-resin.

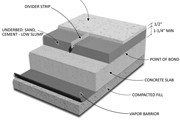

Traditional cement terrazzo is installed over a solid, level concrete foundation that is three to four inches deep. After the forms are removed from the foundation, a one-inch layer of sandy concrete is added.

Before this layer sets, terrazzo workers partially embed metal divider strips in the concrete wherever there is to be a joint or change of color in the terrazzo. For the final layer, terrazzo workers blend and place into each of the panels a fine marble chip mixture that may be color-pigmented.

TERRAZZO SUSTAINABILITY

Today, most of the terrazzo installed is both poly acrylate and epoxy terrazzo. The advantages of this material over conventional cementitious terrazzo includes more and better design options, such as selections of colors.

They can be applied as thin as ¼”-⅜” in thickness, is lighter weight, faster to install, higher strength, and less susceptibility to cracking. Epoxy resin–based terrazzo should only be used for interior applications. Epoxy-based terrazzo will fade from U.V exposure.

Polyacrylate based terrazzo is U.V stable and can be installed to the exterior as well as the interior. Any aggregate like marble blends, mother of pearl blends which is abalone crushed shells, recycled aggregates like glass, porcelain, concrete, and metal can be used in both terrazzo types.

Also shapes and medallions can be fabricated on site by bending divider strips, or sent out to be cut by water jet. When the terrazzo is dry, it can be ground it with various grinders, also referred as floor grinder/polishers. Voids left by the grinding are filled with a matching grout material and hand-troweled for a smooth, uniform surface; it is then cleaned, polished, and sealed.

Components of Terrazzo

Terrazzo divider strips play an important role in the finish of terrazzo. They are used for joints to help control cracking, for pouring by helping maintaining consistent thicknesses, designs, dividing colors and patterns. They come in all shapes and sizes and are made from metals or plastic.